Additive Manufacturing

Ender-3 Pro 3D Printer - Unboxing and Assembling

As a gift for my 18th birthday, my friends bought me the Ender-3 Pro 3D Printer. This was such an amazingly thought out present and I can’t express anything other than gratitude to them. It represented a turning point for the way I design, making me want to create pieces that can be transitioned into the real world.

Ender-3 Pro 3D Printer - Calibration and Fine Tuning

I found out that the 3D printer needed a perfect calibration to obtain good printing. My first attempt to print before printer calibration resulted in an inaccurate printed model. From my discoveries, the printing step must be set to about a half of filament diameter and the printing bed must be perfectly horizontally leveled to obtain good printing results.

Printing the Puppy Model

As the first printing experiment, after assembling and tuning the 3D printer, I decided to print out the puppy model, one of the many printing tests that came already downloaded.

Printing POLYPEARL TOWER TORTURE TEST Model

Next, I wanted to test out the limits and possibilities of my 3D printer, so I downloaded the POLYPEARL TOWER TORTURE TEST MODEL from a specialized site (https://www.thingiverse.com/thing:2064029) and gave it a go. On the first try, I ran into some technical difficulties, but, after some fine-tuning, I managed to print out the entire tower.

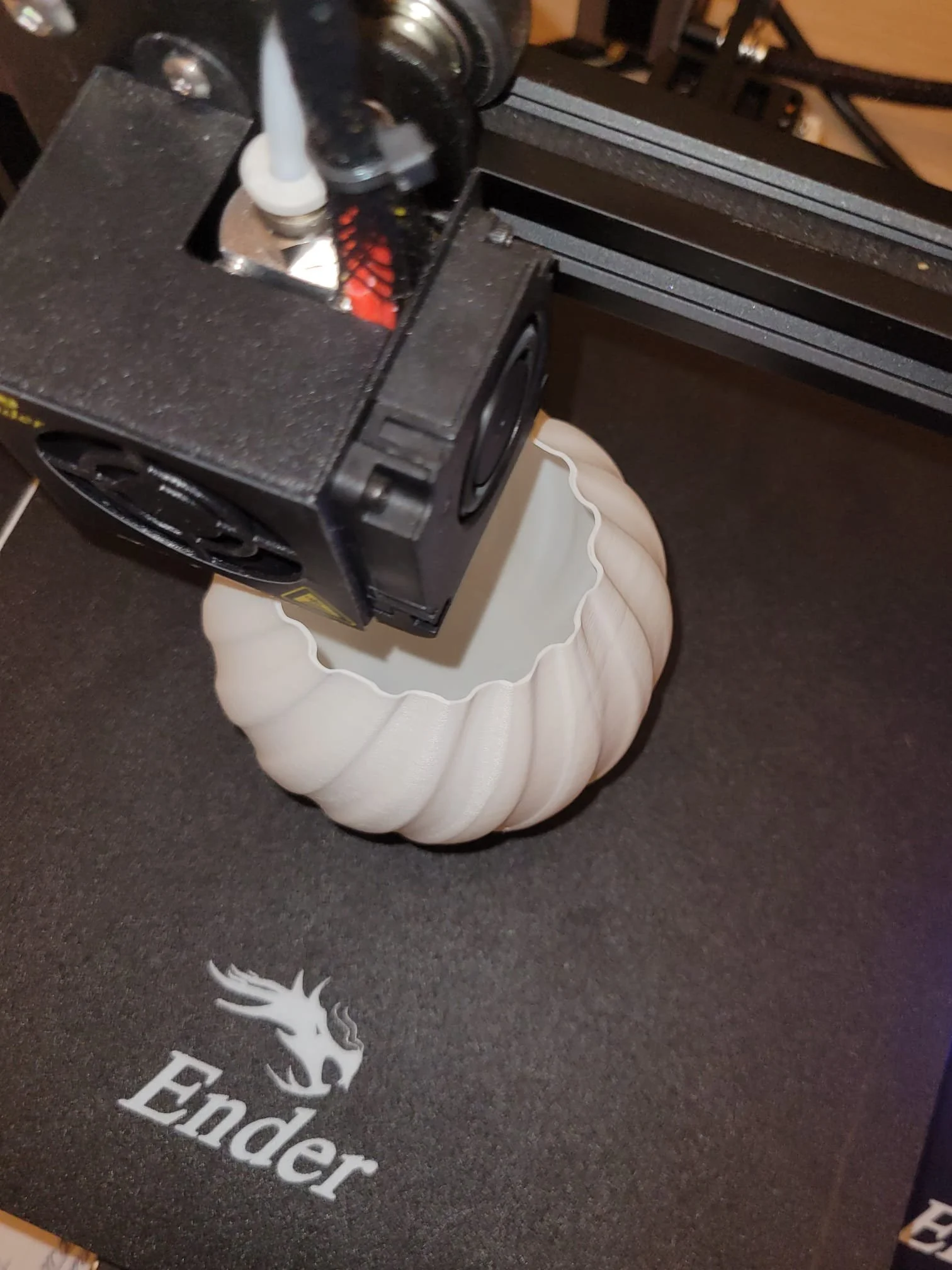

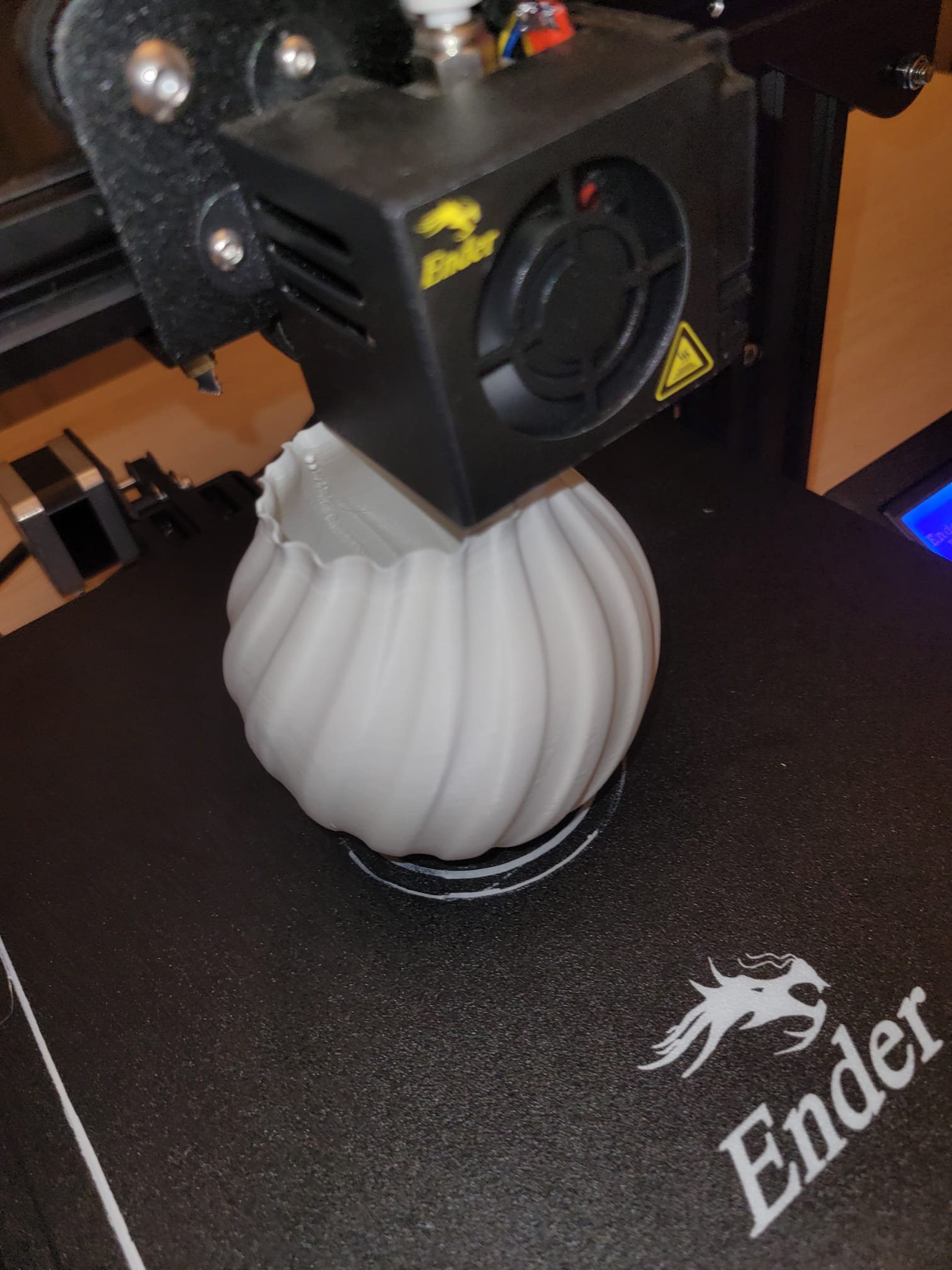

Printing the Vase Model

This vase is one of the first objects I modelled and optimised for 3D printing.

It represented such an exciting opportunity for a young aspiring creator like me: to be able to convert my 3D digital models into something palpable.